In today's competitive business landscape, supplier development has become a critical component for companies aiming to thrive and succeed. Whether you're a small business owner or a corporate executive, understanding supplier development and its potential impact on your supply chain can make all the difference. This strategy focuses on strengthening relationships with suppliers, improving product quality, and enhancing overall efficiency.

Supplier development is not just about managing vendors; it's about fostering partnerships that drive mutual growth. By investing time and resources into supplier development, businesses can achieve better performance, reduce costs, and gain a competitive edge in their respective industries.

In this comprehensive guide, we'll delve deep into the concept of supplier development, its importance, best practices, and how it aligns with modern business goals. Whether you're new to the concept or looking to refine your existing strategies, this article will provide valuable insights to help you navigate the complexities of supplier development.

Read also:The Sweet Spot Cafe Your Ultimate Coffee Haven

Table of Contents

- What is Supplier Development?

- Importance of Supplier Development

- Benefits of Supplier Development

- Key Components of Supplier Development

- Strategies for Successful Supplier Development

- Measuring Success in Supplier Development

- Challenges in Supplier Development and Solutions

- Tools and Technologies for Supplier Development

- Real-World Examples of Supplier Development

- Future Trends in Supplier Development

What is Supplier Development?

Supplier development refers to the strategic process of improving the capabilities and performance of suppliers to meet the needs and objectives of a company. It involves working closely with suppliers to enhance their skills, processes, and resources, ultimately leading to better quality products, improved delivery times, and reduced costs.

This approach goes beyond traditional supplier management, focusing on building long-term relationships rather than short-term transactions. By investing in supplier development, businesses can ensure a reliable and resilient supply chain that supports their growth and success.

Variations of Supplier Development

Supplier development can take various forms depending on the industry and business goals. Some common variations include:

- Supplier training programs

- Joint innovation initiatives

- Capacity building projects

- Technology transfer programs

Importance of Supplier Development

In an increasingly interconnected global economy, supplier development plays a pivotal role in ensuring business continuity and competitiveness. Companies that prioritize supplier development are better positioned to navigate challenges such as market fluctuations, supply chain disruptions, and changing customer demands.

Moreover, supplier development helps foster innovation and collaboration, enabling businesses to stay ahead of the curve in their respective industries. By aligning supplier capabilities with organizational goals, companies can achieve greater efficiency and effectiveness in their operations.

Impact on Supply Chain Resilience

One of the key benefits of supplier development is its impact on supply chain resilience. By strengthening supplier relationships and capabilities, businesses can reduce the risk of disruptions and ensure a steady flow of goods and services. This is particularly important in today's uncertain economic climate, where unexpected events can have far-reaching consequences.

Read also:Joanne Perkins A Comprehensive Guide To Her Life Career And Achievements

Benefits of Supplier Development

Investing in supplier development offers numerous benefits for businesses, including:

- Improved product quality

- Increased cost savings

- Enhanced supplier reliability

- Greater innovation and collaboration

- Strengthened competitive advantage

These benefits not only contribute to the success of individual businesses but also have a positive impact on the broader economy by promoting sustainable growth and development.

Long-Term Value Creation

Supplier development is a long-term investment that yields significant returns over time. By nurturing supplier relationships and capabilities, businesses can create lasting value that extends beyond immediate cost savings. This value creation is essential for achieving sustainable growth and maintaining a competitive edge in the marketplace.

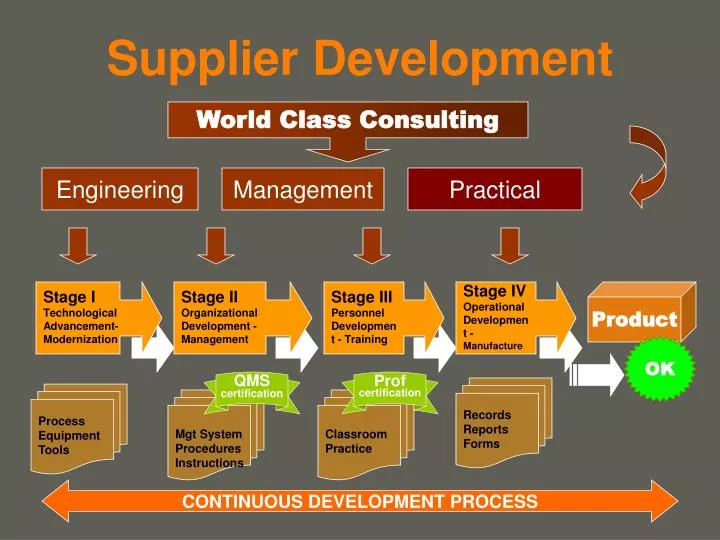

Key Components of Supplier Development

To implement an effective supplier development strategy, businesses need to focus on several key components:

- Supplier selection and evaluation

- Training and capacity building

- Performance monitoring and feedback

- Collaborative innovation and problem-solving

Each of these components plays a crucial role in ensuring the success of supplier development initiatives and must be carefully managed to achieve desired outcomes.

Supplier Selection Criteria

Selecting the right suppliers is the foundation of any successful supplier development program. Key criteria for supplier selection include:

- Technical expertise and capabilities

- Financial stability and scalability

- Geographical proximity and logistics

- Alignment with organizational values and goals

Strategies for Successful Supplier Development

To ensure the success of supplier development initiatives, businesses should adopt the following strategies:

- Set clear objectives and expectations

- Establish open lines of communication

- Provide regular feedback and support

- Invest in supplier training and development

By implementing these strategies, businesses can create a supportive environment that encourages supplier growth and innovation.

Building Trust and Transparency

Trust and transparency are essential components of any successful supplier development program. By fostering an atmosphere of openness and collaboration, businesses can build strong relationships with their suppliers that lead to mutual success and growth.

Measuring Success in Supplier Development

To evaluate the effectiveness of supplier development initiatives, businesses need to establish clear metrics and key performance indicators (KPIs). Common metrics for measuring supplier development success include:

- Product quality and consistency

- Delivery time and reliability

- Cost savings and efficiency gains

- Supplier satisfaction and engagement

Regularly monitoring these metrics allows businesses to identify areas for improvement and make data-driven decisions to optimize their supplier development programs.

Using Data Analytics

Data analytics plays a crucial role in measuring and improving supplier development performance. By leveraging advanced analytics tools, businesses can gain valuable insights into supplier performance and identify opportunities for growth and improvement.

Challenges in Supplier Development and Solutions

While supplier development offers numerous benefits, it also presents several challenges that businesses need to address. Common challenges include:

- Limited resources and budget constraints

- Resistance to change from suppliers

- Cultural and language barriers

- Geopolitical and economic uncertainties

To overcome these challenges, businesses should adopt a proactive and strategic approach, leveraging technology and collaboration to drive success.

Innovative Solutions

Innovative solutions such as digital platforms and collaborative tools can help businesses overcome the challenges associated with supplier development. By embracing these solutions, businesses can streamline processes, improve communication, and enhance overall efficiency in their supplier relationships.

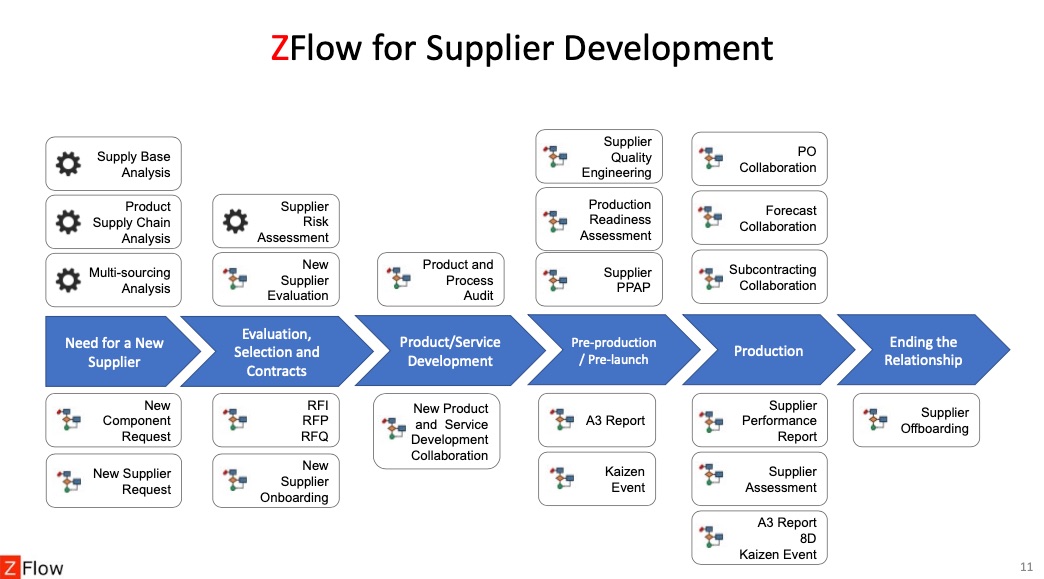

Tools and Technologies for Supplier Development

Advancements in technology have revolutionized the field of supplier development, offering businesses a wide range of tools and platforms to enhance their programs. Some popular tools and technologies include:

- Supplier relationship management (SRM) software

- Collaborative platforms for communication and data sharing

- Performance tracking and analytics tools

- Training and development platforms

By leveraging these tools, businesses can optimize their supplier development initiatives and achieve better outcomes.

Embracing Digital Transformation

Digital transformation is a key driver of success in supplier development. By embracing digital technologies, businesses can enhance their supplier relationships, improve efficiency, and drive innovation in their supply chains.

Real-World Examples of Supplier Development

Several companies have successfully implemented supplier development programs, achieving remarkable results. For example:

- Toyota's supplier development program has been instrumental in its lean manufacturing success.

- Apple's supplier development initiatives have enabled the company to maintain its position as a leader in innovation and quality.

- Nestlé's supplier development programs have helped the company achieve sustainable growth and improve its environmental impact.

These examples demonstrate the power of supplier development in driving business success and creating lasting value.

Lessons Learned

From these real-world examples, businesses can learn valuable lessons about the importance of collaboration, innovation, and long-term commitment in supplier development. By applying these lessons, businesses can create successful supplier development programs that drive growth and success.

Future Trends in Supplier Development

Looking ahead, several trends are shaping the future of supplier development:

- Increased focus on sustainability and environmental impact

- Growing adoption of digital technologies and automation

- Emphasis on diversity and inclusion in supplier relationships

- Rising importance of data-driven decision-making

By staying ahead of these trends, businesses can position themselves for success in the evolving landscape of supplier development.

Preparing for the Future

To prepare for the future of supplier development, businesses should focus on building flexible and adaptable supply chains that can respond to changing market conditions and customer demands. By investing in innovation, technology, and collaboration, businesses can ensure their continued success in the years to come.

Conclusion

Supplier development is a critical component of modern business strategy, offering numerous benefits for companies looking to thrive in today's competitive marketplace. By investing in supplier development, businesses can improve product quality, reduce costs, enhance supplier reliability, and foster innovation and collaboration.

We encourage you to take action by implementing the strategies and best practices outlined in this article. Share your thoughts and experiences in the comments section below, and don't forget to explore other articles on our site for more insights into supply chain management and business growth.